SOLAR FARMS: TIME TO RECYCLE

They’re comparatively inexpensive, climate-friendly and easy to install almost anywhere—photovoltaic systems offer great hope for more sustainable energy production. Unfortunately, such systems have one major weak spot: the materials they’re made of. Each individual panel often has a lifespan of just thirty years, after which it needs to be replaced.

In Europe, the EU Directive on Waste from Electrical and Electronic Equipment (WEEE) has been in place for almost ten years, offering fixed regulation for solar. Based on the principle of producer responsibility, it allows panels to be returned to the recycling loop. Germany, for example, even extends regulations by setting the mandatory minimum recycling rate at 80 percent.

In the United States of America, on the other hand, a nationwide law classifies solar systems as hazardous waste at the end of their service life – only a select few states have made more specific regulatory approaches to the issue. A gigantic amount of waste is looming. According to estimates by the U.S. Environmental Protection Agency (EPA), up to one million tons of solar panel waste is expected to be generated by 2030. By comparison, the total amount of municipal solid waste generated in the U.S. in 2018 was 292.4 million tons. By 2050, the United States will have the second largest amount of end-of-life panels in the world, estimated at 10 million tons.

By 2050, the United States will have the second largest amount of end-of-life panels in the world.

The problem is exacerbated by the fact that the United States are slowly but surely running out of the necessary raw materials for more photovoltaic installations. As a result, the U.S. already has to source many prefabricated solar products from China, making its energy transition dependent on a country with which it has recurring political disputes.

One of the people who has recognized this problem is Suvi Sharma. He teamed up with scientist Dr. Pablo Ribeiro Dias and former Sierra Club National Program Director Jesse Simons. Last year they launched their start-up, Solarcycle. As one of only six U.S.-based companies, Solarcycle has tackled the issue of recycling old solar panels. For one, the technology is still in its relative infancy and also, recycling in the United States is often more expensive than just discarding the outdated cells.

Should the recycling process turn out to be a success, it could solve one of the overlooked problems of the shift to renewable energy.

As Sharma said in an interview with Forbes, “while the end-of-life stream of solar panels is relatively small today, it’s growing extremely rapidly and will continue to for the next twenty years—almost exponential growth.”

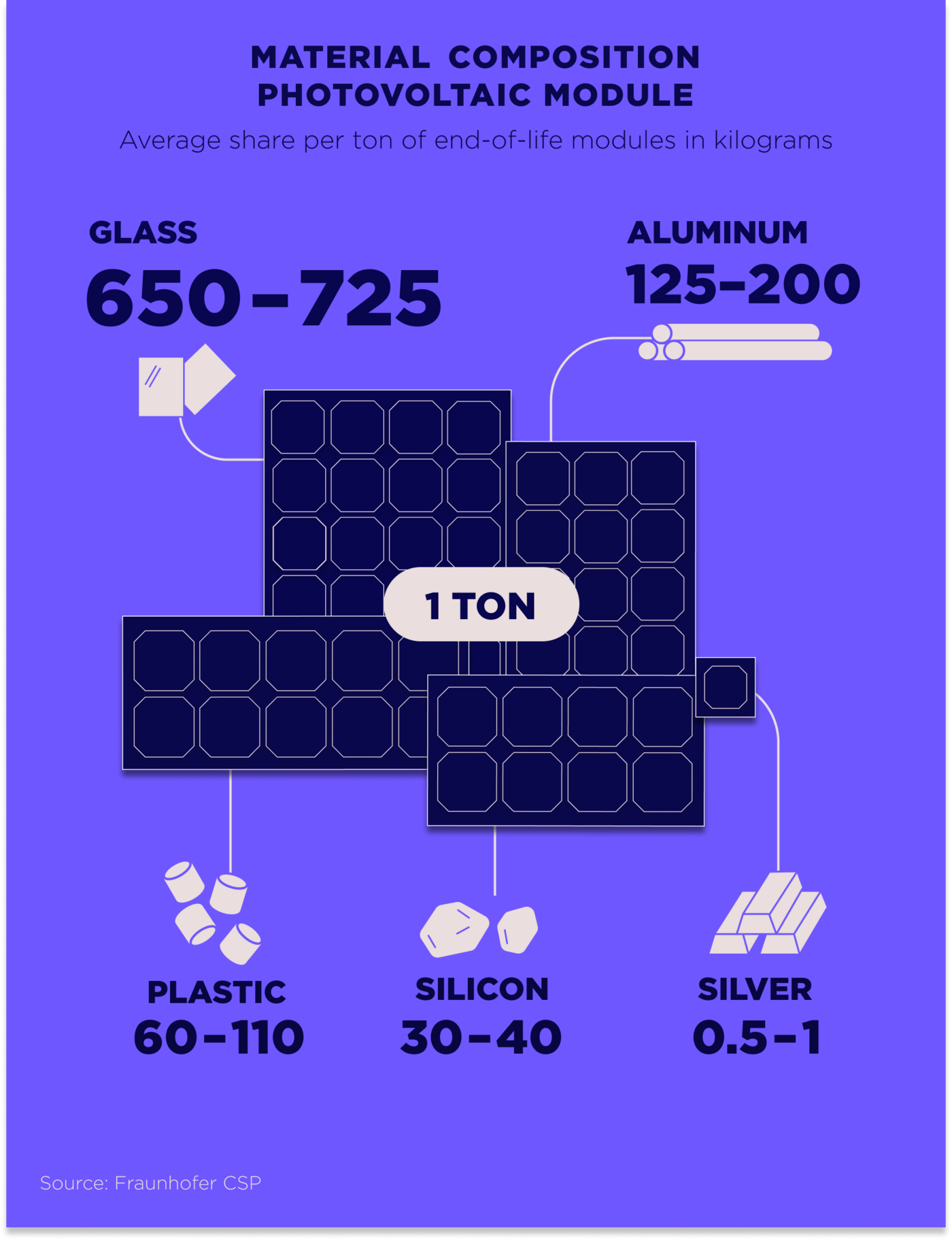

In Solarcycle’s factory in Texas, the team is currently filtering raw materials out of used solar cells, including glass, aluminum, silver, copper and silicon. Sharma says that all of these materials could be reused. The panels being processed come from private households, but also from their first industry clients. For example, the start-up has entered into a partnership with the Danish power company Ørsted for its US business. Soon the Solarcycle site itself will be nearly entirely powered by second-life solar cells, meaning those that still function but were discarded by their previous owners in favor of newer ones.

The company is trying to keep the entire process as simple as possible and thus cost-effective. “We extract the cables, deframe the panel and take away the junction box,” says Dias in a video, describing the initial recycling steps, which are all automated. After that the solar glass is removed. “We [then] liberate and extract the components contained in the solar cell.” This allows the valuable materials to be separated from one another. The company says that it can reuse up to 95 percent of these materials. Dias continues: “It works with any silicon solar panel, no matter how old or how damaged.”

Backed by 30 million U.S. dollars in funding, the start-up is now looking to expand its capacities. After this phase, it hopes to be able to recycle up to one million panels annually.